μMLA

MLA150

MLA300

桌上型雷射直寫曝光機

無光罩雷射直寫曝光機

專業自動化雷射直寫曝光機

CONFIGURABLE AND COMPACT TABLETOP

MASKLESS ALIGNER WITH RASTER SCAN AND VECTOR EXPOSURE

MODULES

可根據需求進行配置

具有光柵掃描和向量曝光模組

THE FASTEST MASKLESS ALIGNER

FOR R&D, RAPID PROTOTYPING AND SMALL PRODUCTION VOLUMES, DESIGNED FOR

BINARY LITHOGRAPHY

最快速無掩模對準器用於研發、快速原型製作和小批量生產,專為二次微影而設計

OPTIMIZED FOR INDUSTRIAL

MANUFACTURING, ENSURING HIGH THROUGHPUT AND SEAMLESS PRODUCTION LINE

INTEGRATION

優化工業製造,確保高通量並實現生產線自動化整合

µMLA 是一款基於穩健的 µPG 平台打造的先進桌上型無光罩雷射直寫曝光系統,該平台是全球最暢銷的台式雷射直寫解決方案。它非常適合作為研發和快速原型製作的入門級工具,能夠在多種應用中實現高精度微結構加工,包括微流控(如細胞分選器件、晶片實驗室)、光罩製作、微光學與微透鏡陣列、感測器製造、MEMS,以及二維材料和扇出電極(fan-out electrodes)的圖案化。

µMLA 通過兩種不同的曝光模式提供靈活性:

-

光柵掃描模式(標準):

確保快速曝光和出色的圖像品質,無論結構尺寸和圖案密度如何,都能保持一致的寫入時間。 -

向量掃描模式(選配):

專為連續、平滑的曲線而設計,是波導等結構的理想選擇,兼具速度和精度。

三種光學配置可在解析度和輸送量之間實現可定制的平衡,切換方便,可針對特定應用進行優化。 其他功能包括:

-

繪製模式:

對現有圖案和電極觸點進行即時調整,適用于納米線或二維材料。 -

灰度模式:

支援 2.5D 結構,適用於複雜的微光學器件。

µMLA 桌面式設計,可放置於標準工作台上,提供一套全面的功能,適用各種高品質光刻應用。

請聯繫我們,進一步瞭解µMLA 及其如何滿足您的研發需求;從CAD到曝光只需幾分鐘,而非數周。

您是否因光罩成本高、交貨期長而感到推進遲緩?您是否希望不需要對傳統光罩對準器進行冗長的培訓就能立即執行設計?

探索MLA 150 和數字光刻世界

這種現代化的無光罩激光直寫系統採用快速、靈活、易於使用的解決方案取代傳統技術,具有最高的性能。通過使用數字微鏡器件(DMD)作為動態掩模,MLA 150 克服了物理光罩的缺點。從數位設計到完美圖案化的基底只需幾分鐘,使您的使用者能夠加速量子器件、微機電系統、微光學和生命科學等領域的研究。

為什麼MLA 150 是實驗室的理想選擇?

MLA 150從設計之初就致力於解決學術和工業研發機構面臨的核心挑戰,它直接解決了光罩前置時間長、經常性成本高以及傳統系統曲線陡峭等問題。

專為多用戶設施而打造

減少培訓開銷,並最大限度地延長工具正常執行時間。MLA 150 非常直觀,新用戶只需不到一個小時就能完全勝任獨立工作。其操作軟體和簡化的工作流程非常適合共用實驗室環境,這也是MLA 150 成為領先全球潔淨室必備工具的原因所在。

先進科研及更多應用的卓越靈活性

您的工作獨一無二,您的光刻設備亦當如此。無論是推進前沿研究、通過快速原型加速創新,還是進行高品質的小批量生產,MLA 150 都能適應您的需求,而不是讓您適應設備。

-

廣泛相容各類光阻:

同時安裝一個或兩個不同的雷射波長(375 nm 和/或 405 nm),無需更改硬體即可曝光所有線寬、g、h 和 i 線光阻。 -

輕鬆應對複雜基材:

專用真空吸盤可讓您輕鬆處理難以處理的樣品,包括小至 3×3 mm²的小基片、薄箔和翹曲晶片。 -

創建 2.5D 高深寬比結構:

使用灰度曝光模式可製造複雜的 2.5D 微結構,或使用高深寬比模式在厚光刻膠中形成陡直的側壁圖形,非常適用於 MEMS 和微流體應用。 -

互動式 繪製模式:

在樣品的即時攝像圖像上直接繪製和曝光圖案,特別適用快速製作原型或在石墨烯薄片、奈米線等特殊結構上精確定位電極。

高產速、高精度、不妥協

使用者友善並不等同低性能。MLA 150以卓越的速度和精度,突破製造的極限。

-

亞微米級解析度:

實現最小0.45微米特徵尺寸,輕鬆製備複雜高解析度器件。 -

卓越產能表現:

單次曝光150mm晶片僅需不到16分鐘。 -

先進的自動對準系統:

250奈米級對準精度,數位化補償偏移、旋轉、縮放及剪切誤差 —物理光罩無法實現的精准調整。 -

完美對焦:

動態自動對焦系統確保圖形清晰均勻,輕鬆應對圖案化、翹曲及脆弱基材。 -

極致環境穩定性:

集成溫控層流環境艙(±0.1°C精密控溫),有效抑制熱膨脹效應,確保結果穩定可重複。

大幅降低運營成本

徹底消除光刻工藝中最大且持續的成本——光罩。MLA 150無需光罩採購,省去數周交期等待,同時免去清洗、存儲流程,規避高額破損風險。結合10-20年超長雷射壽命及簡易維護,MLA 150實現行業領先的綜合持有成本。

主要應用

從基礎物理學到應用生物科學,MLA 150 都是值得信賴的工具:

-

奈米加工:

量子設備、二維材料、半導體奈米線 -

MEMS 和 MOEMS:

感測器、致動器、微光元件、微流道 -

材料科學:

新型材料的圖案化加工 -

生命科學:

晶片實驗室、生物感測器

攜手全球數百家頂尖科研機構

全球數百所一流大學和研究中心已選擇MLA 150替代傳統光刻機。

立即聯繫我們,瞭解如何為您的用戶賦能,實現實驗室技術升級。

無光罩對準器MLA 300 專為大批量生產而設計,在工業光刻領域具有無與倫比的靈活性和精確性。它支援最大 300 x 300 mm的晶片,能動態適應表面變化,無需昂貴且耗時的光罩生產。通過用直接資料曝光取代傳統光罩,MLA 300 可為先進封裝、感測器校準和微機電系統製造等複雜光刻挑戰提供創新解決方案。其高通量、1.5 μm 解析度、簡化的工作流程以及與製造執行系統 (MES) 的無縫集成,使其成為包括微流控設備和其他先進技術在內的各種應用的理想選擇。

主要功能

-

高通量生產:

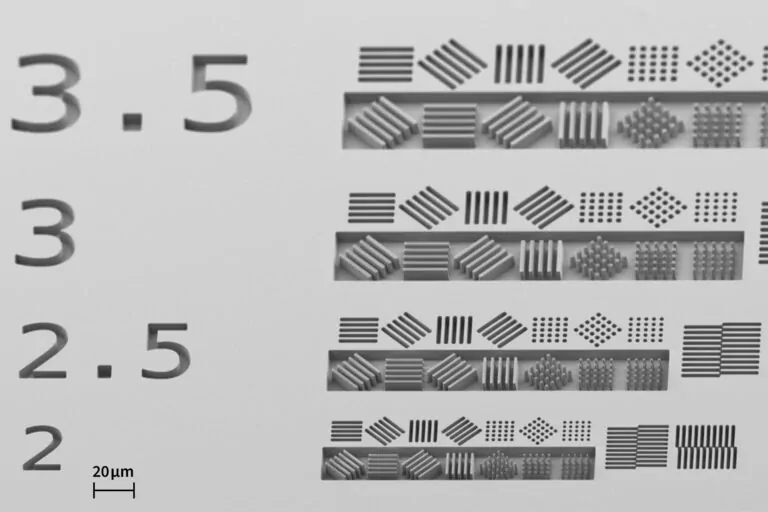

針對工業規模生產進行了優化,最小特徵尺寸為 1.5 µm。對於更高產量需求,我們還提供最小特徵尺寸為 3 µm 的高通量寫入模式。 -

高精度:

該系統具有卓越的光學品質,確保在各種具有挑戰性的基底上實現精確製圖。 -

全自動化:

MLA 300 具有全自動化功能,包括可定制的裝載選項、專為生產環境設計的高級軟體以及與 MES 系統的集成。 -

獲得專利的基板跟蹤技術:

即時自動對焦可補償基板翹曲或波紋,確保在所有表面上實現完美無瑕的圖案化和均勻性。

應用

-

先進的封裝:

可進行扇出型晶片封裝,並補償晶片偏移和晶片高度變化。 -

感測器和感測器積體電路:

專為高精度感測器製造設計,確保精確和可定制的圖案化。 -

MEMS 和微流控器件:

非常適合 MEMS 和微流控應用中所需的複雜設計。 -

分立電子元件:

支持高精度、高適應性的各種電子元件的生產。 -

積體電路和專用積體電路(ASIC):

針對高效生產模擬和數位積體電路以及專用積體電路進行了優化。 -

探針卡:

通過確保精確的圖案化和對準,實現高精度探針卡生產,從而提高測試和檢驗效率。 -

電力電子:

針對陶瓷等基材進行了優化,可克服翹曲和厚度變化,提供穩定的品質。 -

OLED 顯示幕:

高精度和高靈活性使MLA 300 成為 OLED 顯示幕製造的理想選擇。

工作流程和成本效益

-

無光罩直寫技術克服了傳統光罩系統的局限性,為晶片圖案校正、品質控制序列化以及感測器應用中的校準追蹤提供了靈活的框架。

-

MLA 300 無需進行光罩採購、驗證和管理,從而簡化了生產流程,直接從資料曝光設計,降低了時間和複雜性。

-

MLA 300 憑藉其先進的功能提高了良率,特別是在熱處理等具有挑戰性的基板應用中。

-

即時自動對焦系統可補償基板翹曲或波紋,即使在不平整的表面上也能確保完美的圖案化。

-

該系統採用長壽命二極體激光,在 24/7 全天候生產情況下估計可使用長達 10 年,而且系統極低的耗材需求,最大限度的降低運營成本。

-

模組化設計便於快速維護,最大限度減少了停機時間。

欲瞭解更多關於無光罩對準器MLA 300,以及它如何優化您的高通量微加工流程,請聯繫我們。

PRODUCT HIGHLIGHTS

Direct-write Lithography No mask-related costs, effort, or security risks Exposure Quality Edge roughness raster mode 100 nm; vector mode 30 nm; CD uniformity 200 nm Exposure Speed 4″ wafer in 90 minutes Grayscale Lithography With up to 256 gray levels, the grayscale exposure capability is part of the standard configuration Small Footprint 640 mm x 840 mm x 530 mm / 25″ x 33″ x 21″ – the smallest tabletop maskless lithography tool Flexible Configuration Choice of exposure wavelength; a choice of Raster and Vector Scan Modules Flexible Use Software enables easy switching for variable resolution and throughput speeds User-friendly Intuitive software and tool operation; easy handling of small samples Plug-and-play Setup Simplified plug-and-play installation reduces overall implementation time and saves costs

多用戶實驗室的理想之選

用戶培訓僅需不到1小時

快速準確的對準

250nm正面/背面對準及誤差補償

卓越的工藝靈活性

雙雷射並行配置,全面覆蓋各類光阻

多種曝光模式可選,兼顧效率與精度

配備專用真空吸盤,輕鬆應對小型基板、薄膜及翹曲樣品

低成本與易維護性

雷射壽命長達 10-20 年

直寫光刻技術

零光罩成本,免維護,無安全風險

灰度光刻模式

輕鬆實現2.5D結構

曝光品質

邊緣粗糙度60nm、CD均勻性100 nm、自動聚焦補償翹曲/波紋基板

最小特徵尺寸

提供兩種不同的寫入模式,最小特徵尺寸可達 0.45 μm

方便用戶

專用軟體與標準化工作流程,操作直觀高效

曝光速度

405nm雷射波長下,150mm晶片全程<16分鐘

Maximum exposure area: up to 400 x 400 mm² Maximum substrate size: 17" x 17" Professional Grayscale Mode Multiple Write Modes Minimum feature size down to 0.5 µm Maximum exposure speed (at 1.3 µm feature size): 370 mm²/ minute Address grid down to 5 nm Modular configuration concept to fit customer application Realtime autofocus Stage map correction Camera system for measurement and inspection Automatic loading system Customer specific laser Multiple data input formats (DXF, CIF, GDSII, Gerber, STL, BMP)

Direct-write Lithography No mask-related costs, effort, or security risks Flexibility Direct writing in industrial production allows per-die pattern corrections, e.g. to react to distortions or process variations and serialization Time-saving Shorter time from prototyping to production. Digital design management replaces conventional mask librarys Exposure Quality Optical compensation of scaling, rotation; patented substrate tracking technology Dynamic Autofocus Superior critical dimensions (CD) uniformity on warped or corrugated substrates Exposure Speed 300 x 300 mm2 in 5 minutes (write mode 3, two exposure modules) Full Facility Integration Customizable automatic loader, substrate chuck including warped substrates, custom workflow “wizards” and interface with manufacturing execution systems (MES) User-friendly Intuitive software and tool operation; easy handling of small samples User-friendly SEMI-compliant user interface; customized workflow “wizards” for system operators

AVAILABLE MODULES

Raster Scan Exposure Mode Fast with excellent image quality and fidelity; write time is independent of structure size or pattern density. LED light source at 365 nm or 390 nm Vector Scan Exposure Mode Patterning continuous structures consisting of curved lines – where smooth contours are required. Laser light source at 405 nm and/or 375 nm Three Optical Setups Min. resolution of 0.6 µm, 1 µm and 3 µm; variable resolution within each mode Optional Overview Camera Fast and easy location of alignment marks or other features of interest on substrate Glovebox Integration Glovebox for patterning of sensitive materials in a controlled Nitrogen environment Draw Mode Import and overlay of BMP files on top of the real-time microscope image — as in a virtual mask aligner; simple lines and shapes can be drawn into the real-time camera image for immediate exposure Optical Autofocus Perfect exposure of small samples (<10 mm) Exposure Area Can be upgraded from 100 x 100 mm2 to 150 x 150 mm2 Choice of Exposure, Wavelength and Source Raster Scan Mode: LED light source at 365 nm or 390 nm. Vector Scan Mode: Laser light source at 405 nm and/or 375 nm

Exposure Wavelength

Diode laser sources at 375 nm and/or 405 nm can be mounted

together and used interchangeably to expose different photoresists

Exchangeable Chucks

Additional vacuum chucks for challenging samples like

small substrates, foils, or warped substrates

Customized vacuum chuck layout upon

request

Draw Mode

mport and overlay of BMP files on top of the real-time microscope

image – as in a virtual mask aligner; simple lines and shapes can be drawn into the

real-time camera image for immediate exposure

Autofocus

Air-gauge or optical autofocus for perfect exposure of small samples

(less than 10 mm)

Variable Substrate Sizes

From 3 mm to 6”; up to 8” upon request

Advanced Field Alignment

Automatic field-by-field alignment on individual dies

on the wafer for superior alignment accuracy

Automated Loading Module SEMI-standard BOLTS plane can be configured for open cassettes or Load Ports for FOUP. The number and configuration of ports can be selected and customized for round or rectangular substrates Manufacturing Execution System (MES) Patterning continuous structures consisting of curved lines – where smooth contours are required. Laser light source at 405 nm and/or 375 nm Backside Alignment Visual or through-wafer IR backside alignment available with 1 µm positioning accuracy Exposure Wavelengths High-power diode lasers with 7 W at 375 nm or 20 W at 405 nm with long lifetime are available Multipurpose Vacuum chuck Customized vacuum chucks are available for applications with special substrates (e.g. warped panels) Service Contracts Service contract grades for faster on-site support and participation in the spare parts pool

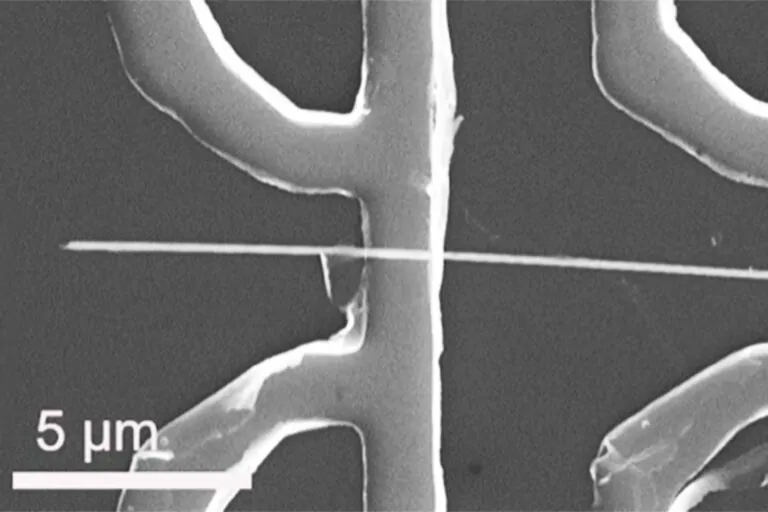

Single Ni nanowires (horizontal line in the image) with two precisely aligned thermometer structures used to investigate Co-Ni alloy magneto-thermopower and magneto-resistance. (Courtesy of Tim Boehnert, University of Hamburg)

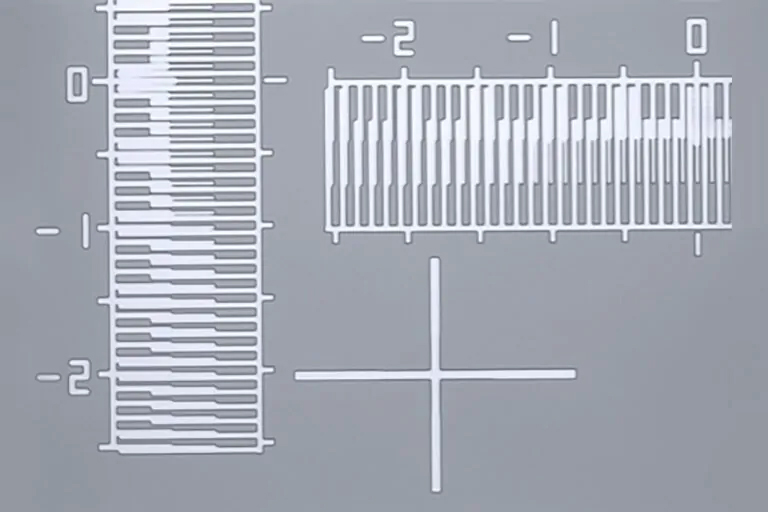

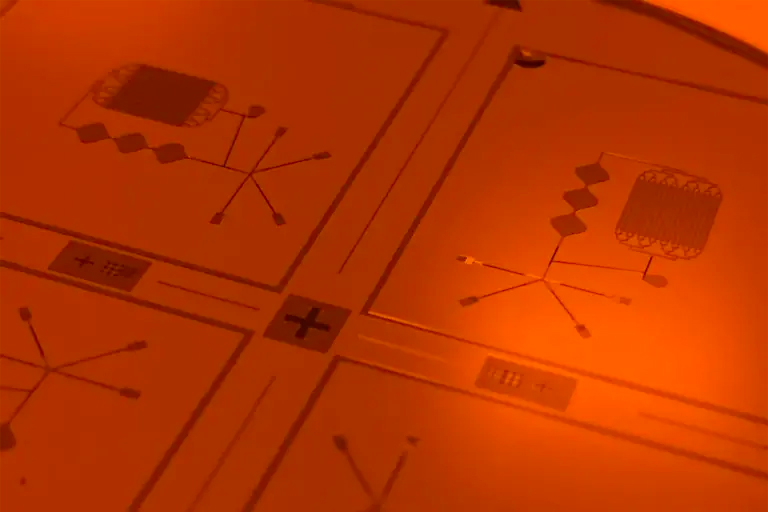

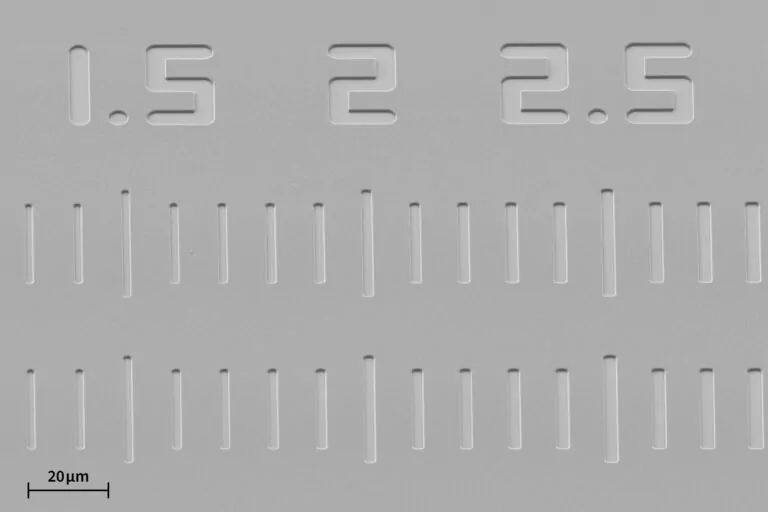

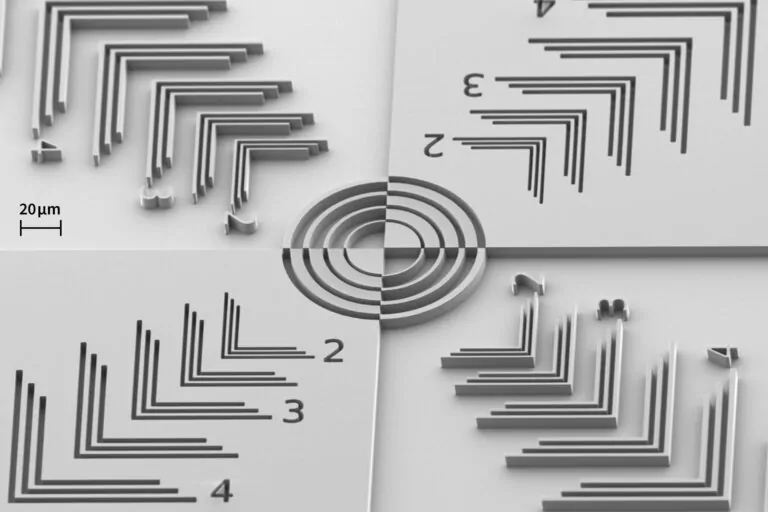

In many applications, several layers need to be exposed on the same substrate. The cameras of the μMLA can automatically detect alignment markers and adjust the position, rotation, scaling and orthogonality of the exposure to the existing structures. The image shows vernier scales and a “cross-in-cross” structure, employed to measure the remaining offset in x and y direction.

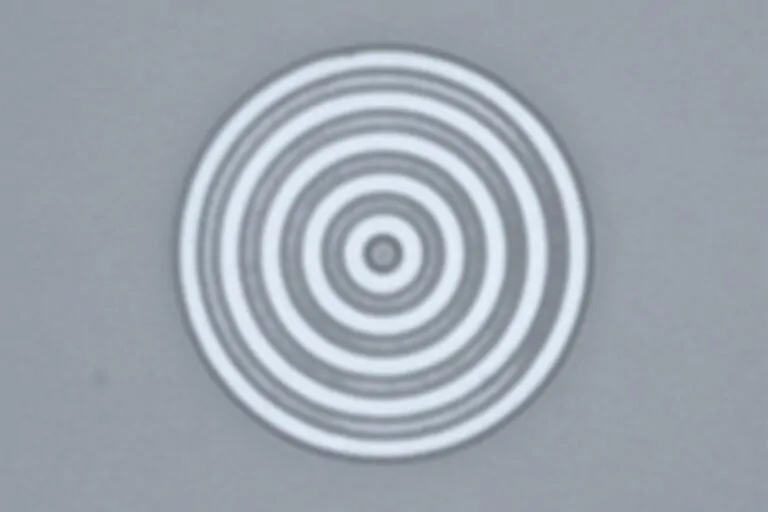

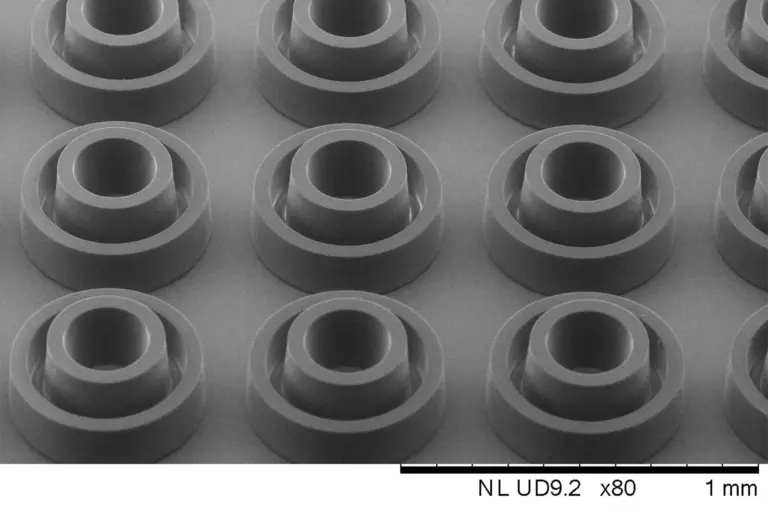

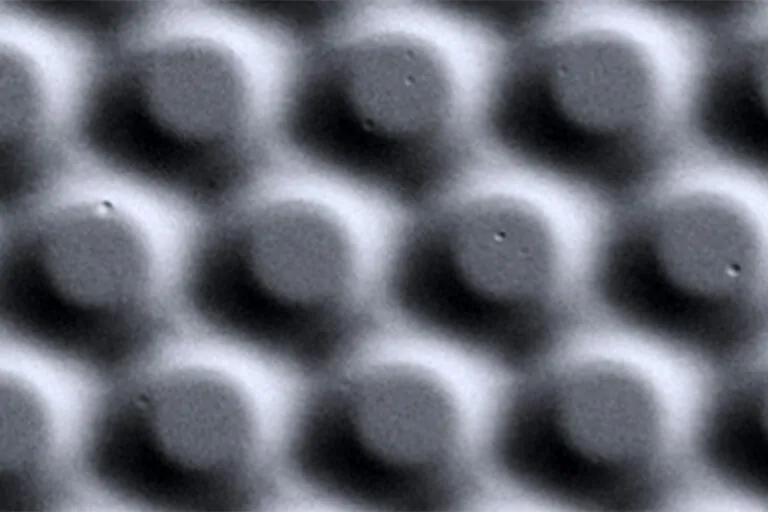

Concentric rings with 1 μm line width were written into the photoresist using the Raster Scan Exposure Mode.

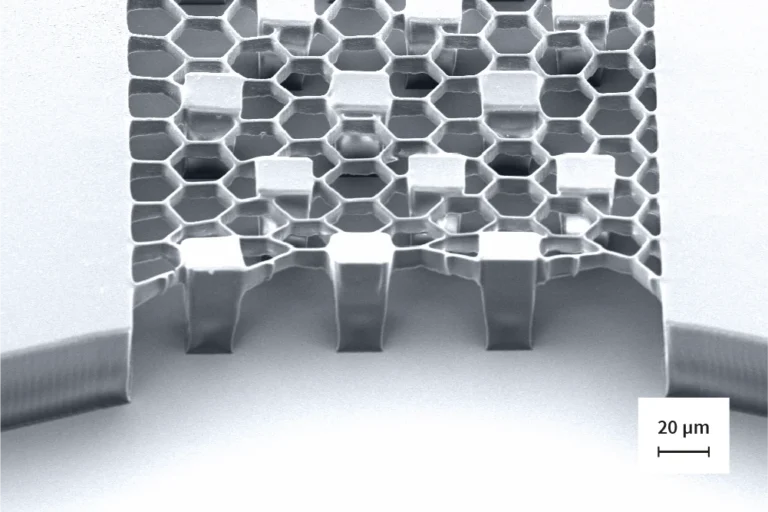

Dual-compartment microcontainers for combination therapy, to achieve a physical separation of two drugs followed by a sequential release. The corresponding paper is linked in our library (DTU Kopenhagen: Christfort, J. F., et al. Adv. Therap. 2022, 5, 2200106)

Micro fluidic structures made in two layers of materials: 1. AZ10XT (14 µm, thermally cross-linked by customer) and 2. SU-8 (20µm, aligned to first layer) (Courtesy of Max-Planck-Institute for terrestrial microbiology)

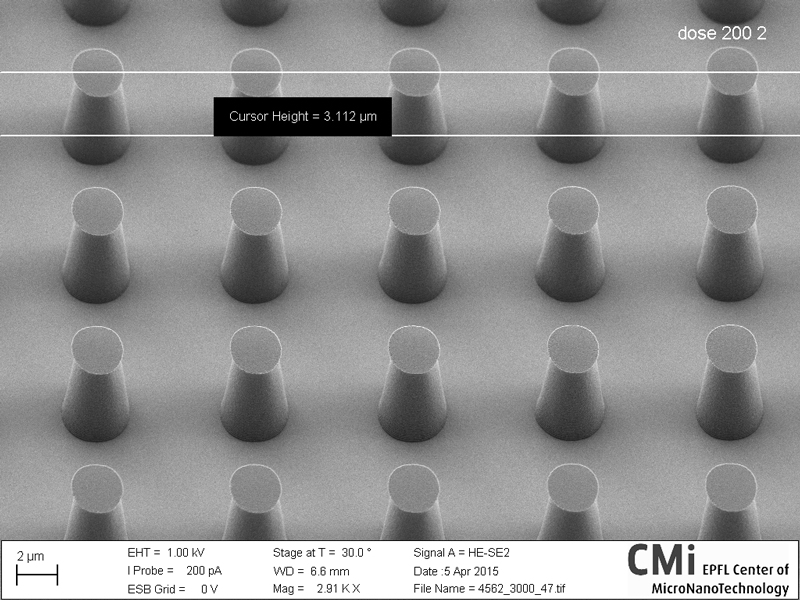

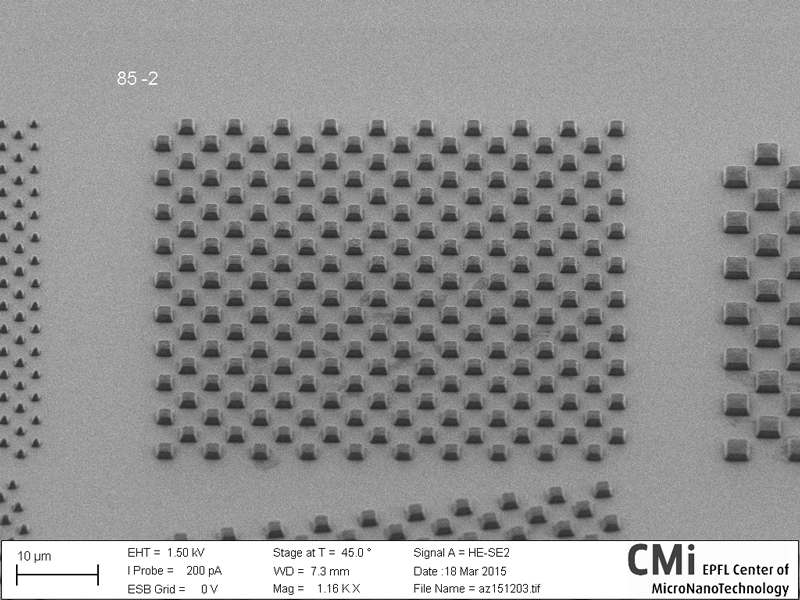

The μMLA also offers a standard Grayscale mode, which allows the creation of structures for a wide range of applications in micro-optics. This example shows micro-lenses written in 15 μm thick AZ4562, with a pitch of 30 μm and a radius of curvature of 16 μm.

Realization of doubly reentrant structures using AZ nLoF 2070 exposed in three steps. Read the application note to learn about the fabrication process.

Microfluidic channels and lattice structures with suspended features fabricated in mr DWL40. Read the application note to learn about the fabrication process.

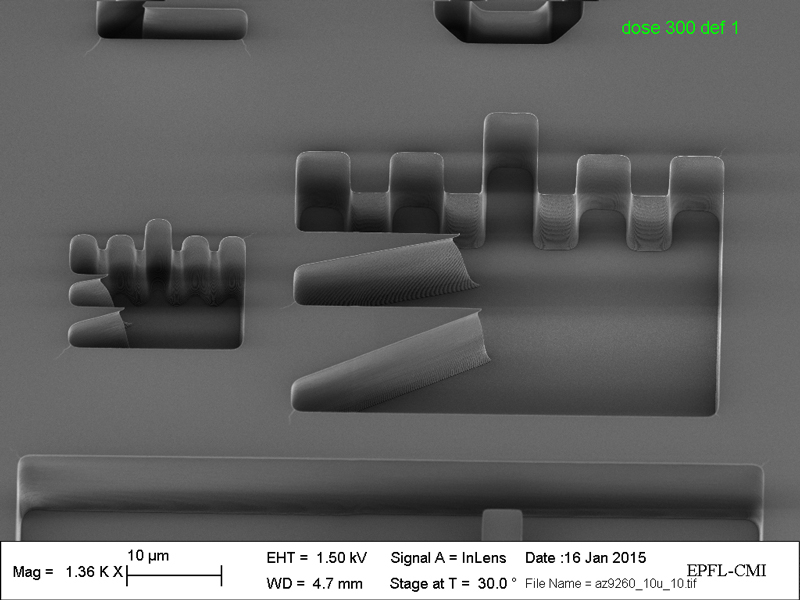

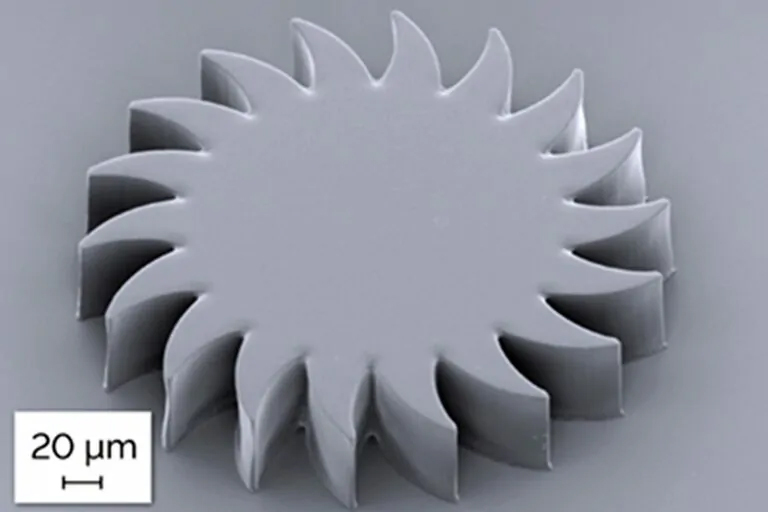

A gear wheel patterned in 800 µm thick SU-8 demonstrates the capability of the MLA 150 to create vertical sidewalls in thick forks, gear wheels, piezoelectric material, bio-, chemical or pressure sensors, or other miniaturized physical devices.

A master for a microfluidic mixer to be transferred by soft lithography in PDMS. The structure is patterned in 100 μm SU-8 with the 375 nm laser wavelength of the MLA 150. This type of structure requires high-throughput for fast large-area patterning and precise stitching to ensure channel smoothness. (Courtesy of CMi EPFL Center of MicroNanoTechnology)

Nanoholes as precisely positioned traps for nanoparticles fabricated using “mix-and-match” lithography. The 100 nm square “nanoholes” patterned with e-beam lithography are separated by the coarse trenches created using the MLA 150, which are precisely aligned to the existing nanohole pattern. (Courtesy of EPFL LMIS1, Lausanne)

An array of SQUIDs (superconducting quantum interference device) used for the readout of metallic magnetic microcalorimeters (high-resolution particle detectors operated at low temperatures). These devices are microfabricated in large arrays and comprise up to 18 layers with submicron features. The MLA 150 ensures the extreme overlay accuracy crucial for this application. (Courtesy of the Kirchhoff Institute for Physics (KIP), Heidelberg University)

This specific patterning of “OSTEmers” retinal implants shows an example of novel medical implants. Bio-compatible, impermeable, and UV-curable OSTEmers are highly promising for artificial retina. Contactless exposure with the MLA 150 enables the patterning of this material, which is a viscous liquid during processing, and is virtually impossible to work with using other lithography tools. (Courtesy of EPFL, Neuroengineering Laboratory)

A wafer of superconducting detectors for the South Pole Telescope (SPT) camera. The camera carries an array of over 16000 such devices. Each of them comprises ultra-thin superconducting elements with features as small as 1 μm. Here, the MLA 150 was used to fabricate the Nb leads, which appear as bands in between the pixels. (Courtesy of CNM at Argonne National Laboratory, photo by Clarence Chang)

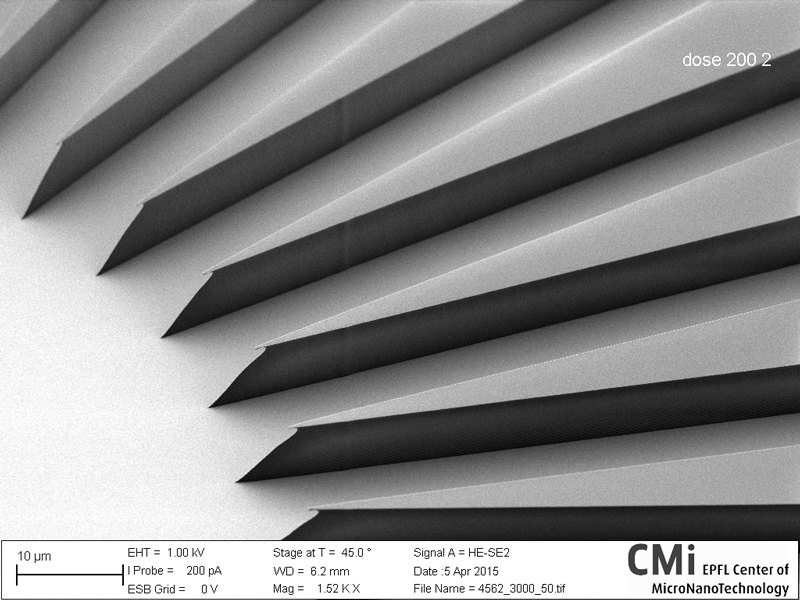

Resolution pattern exposed in a 500 nm layer of AZ1500 showing a minimum feature size of 1.5 µm. (SEM image, viewed with a 45° angle)

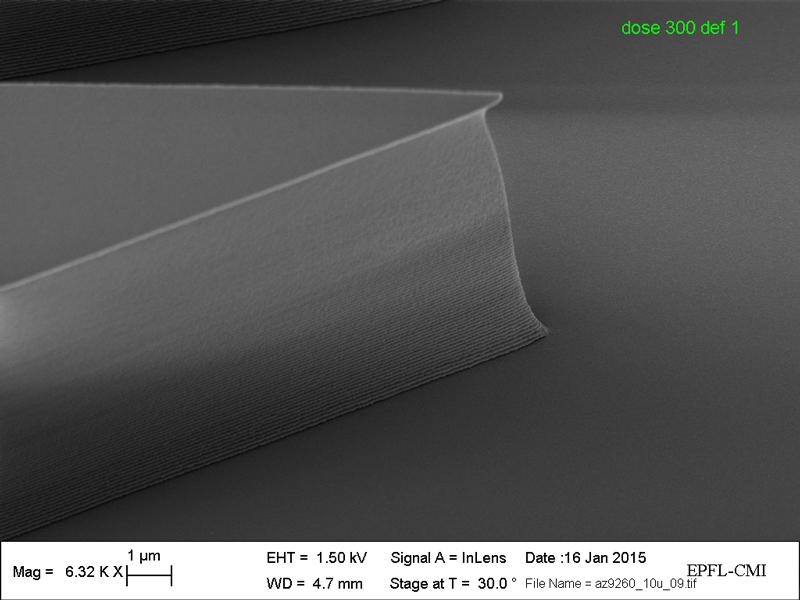

Test structures exposed in a 10 µm layer of AZ 10XT. (SEM image, viewed with a 45° angle)

Resolution pattern exposed in a 10 µm layer of AZ 10XT showing an aspect ratio of 1:5. (SEM image, viewed with a 45° angle)

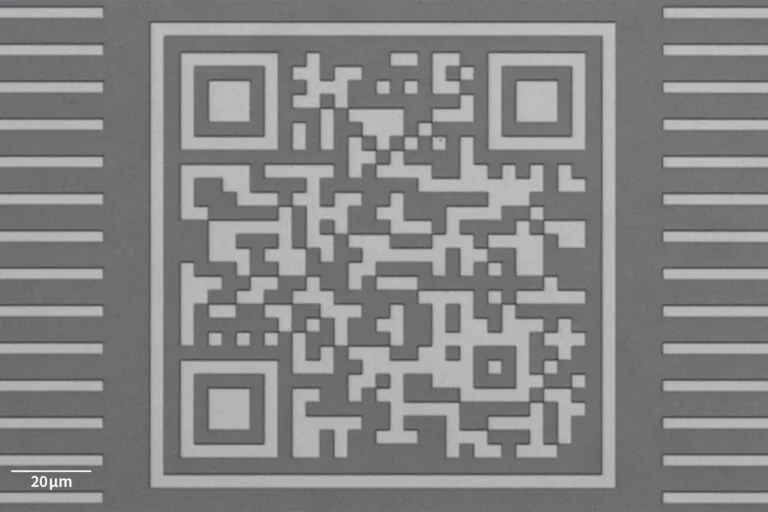

Optical microscope view of a micro QR code exposed in AZ1500 (500 nm) resist.

MEMS processes integrate standard microchip technologies with electromechanical components of a diverse range of sizes and materials. Stresses and stress-induced deformations need to be managed carefully to yield correct device properties. The Maskless Aligner technology is ideally suited to make on the fly corrections to the design, if required.

Structuring flexible substrates is challenging as the shape and the distortions vary with applied forces. Maskless lithography offers the unique option of exposing the substrates with warpage-dependent pre-distortions, to maximize yield.

Reach Us

想要知道更多資訊嗎? 沒問題,快與我們聯繫!

© Stella Technology Co., Ltd.