VPG+ 200

VPG+ 400

VPG+ 800

VPG+1400 FPD VPG+1850 FPD

VPG 300 DI

專業光罩製版系統

大型光罩製版系統

先進雷射直寫圖型發生器

POWERFUL PRODUCTION TOOLS FOR STANDARD PHOTOMASKS AND MICROSTRUCTURES IN I-LINE RESISTS

適用 I-LINE 光阻的標準光罩和微結構的強大生產工具

DESIGNED FOR PHOTOMASK PRODUCTION ON LARGE SUBSTRATES IN DISPLAY APPLICATIONS

專為顯示器應用領域大型基板光罩生產而設計

THE MASKLESS DIRECT IMAGER VPG 300 DI

FOR HIGH ACCURACY AND HIGH RESOLUTION MICROSTRUCTURES

快速展現高精度、高分辨率的微型結構

VPG+ 200、VPG+400、VPG+800體積圖案生成器是功能強大且多用途的光刻系統,專為i-line光阻的多用途光罩製造而設計。這些系統擅長在從小型到大型各種尺寸的基板上創建高解析度圖案,最大可處理達800 x 800 mm²的基板。VPG+ 系列是先進行業廣泛應用的理想選擇,其設計旨在滿足現代微納加工不斷發展的需求。

所有VPG+ 型號均配備解析度達10 nm的干涉儀,可實現高品質快速曝光與極高精度對準。 Mura優化技術確保卓越的關鍵尺寸均勻性與解析度,而封閉式環境室室符合先進光罩製造最嚴苛的要求,全方位保障穩定的產品品質。

升級光罩製造產能

-

先進封裝:

在扇出型封裝、仲介層技術及其他尖端封裝工藝的光罩製造中,確保卓越精度與速度。VPG+系列可輸出高解析度圖形,滿足高性能光罩的嚴苛要求。 -

電子製造:

將體積圖案生成器無縫集成到您的工作流程中,用於製造PCB、IC及其他電子元件所需的光罩,實現高效協同生產。 -

微流控與MEMS:

讓微流道晶片和MEMS的創新設計快速落地。VPG+系統生成複雜精密圖形的能力,使其成為這些快速發展領域光罩製造的理想解決方案。 -

智能手機顯示器:

以極致精度與速度生產最先進的智慧手機光罩。VPG+系統為高品質LCD、LED及OLED顯示器提供所需的解析度與精確度保障。

卓越性能與高效能完美融合

-

高功率 DPSS 雷射器:

確保精確圖形生成,帶來卓越光罩品質與增強器件性能。 -

高速曝光引擎:

大幅縮短寫入時間,實現快速光罩製造與提升產能,輕鬆應對緊急需求。 -

自動校準系統:

保障超精密圖形對準與定位,有效節約生產時間並最大限度降低誤差。 -

閉環環境控制室:

維持最佳生產條件,確保每個製造週期的一致性品質,滿足最嚴苛的制程標準。 -

寬幅面靈活性:

VPG+ 800專為中大型基板,VPG+ 200/400則精准適配中小型規格。 -

無縫集成能力:

全系列支援工業標準資料格式,確保與現有設計製造流程完美相容。 -

結構緊湊設計:

在強大性能基礎上,創新結構設計可適配空間受限的生產環境,以精巧形態釋放極致效能。

投資微納加工的未來

VPG+系列為您的微納加工需求提供面向未來的解決方案。無論您專注於小型、中型還是大型光罩製造,這些系統都能提供推動工藝進步所需的靈活性、精度與速度。

採用VPG+系統,您將實現:

- 提升光罩品質與解析度,實現卓越的設備性能

- 提高產能效率,加速光罩製造,縮短產品上市週期

- 通過高效運營與可靠性能,顯著降低生產成本

- 獲得隨著發展持續升級的光罩製造擴展能力

開啟光罩製造新紀元

立即聯繫我們,瞭解行業領先技術如何重新定義您的微納加工流程。

突破性效能與卓越品質的完美融合 — VPG+ 1400 FPD與VPG+ 1850 FPD為全球光罩製造商大規模生產的終極解決方案,專為顯示器行業量身定制。這是我們迄今最大規格的系列設備,支援最高G8.6規格的大尺寸光罩高速圖形生成,最大曝光面積達1400 x 1800 mm²,為立志引領平板顯示器行業發展的製造商提供最優選擇。

VPG+ 1400 FPD與VPG+ 1850 FPD採用差分干涉儀系統,解析度高達1.2 nm,可實現高精度對準的高速高品質曝光。Mura優化技術確保卓越的關鍵尺寸均勻性與解析度,封閉式環境控制室滿足先進光罩製造最嚴苛的標準要求,為顯示器面板行業提供終極量產解決方案。

提升平板顯示器製造新境界

-

完美品質:

VPG+ 1400 FPD與VPG+ 1850 FPD專為製造高解析度光罩(包括半色調光罩)而優化,適用於生產平板顯示器(FPD)關鍵元件:彩色濾光片(CF)、薄膜電晶體(TFT)陣列、氧化銦錫(ITO)電極、觸控面板(TP)、精細金屬罩(FMM)、有源矩陣有機發光二極體(AMOLED),以及其他液晶顯示器(LCD)與有機發光二極體(OLED)相關功能層。 -

卓越生產效能:

VPG+ 1400/1850 FPD具備非凡的產能表現,確保快速完成光罩製造,滿足大規模顯示器面板生產需求,助力優化整條產線效率。 -

極致精度與可靠性:

VPG+ 1400/1850 FPD提供大尺寸光罩精密圖案生成所需的解析度與精度,保障設計圖案的完美轉移。設備支援24/7穩定運行,確保交付週期準確可控。 -

先進計量技術:

集成計量套件與工具匹配功能,為大尺寸灰階光罩生產提供精准的二次對準能力。

提高最大化性能

- 高速曝光引擎與高功率DPSS雷射器顯著縮短寫入時間,助您加速光罩生產,最大化產出效能。

- VPG+ 系統具備卓越的亞微米級解析度與成像品質,確保設計圖案精准轉移至光罩,實現完美顯示效果。

- 自動校準工具通過保證超精密圖形對準與定位,有效優化工作流程,既節省時間又最大限度降低誤差。

- 大尺寸精密平台配備柔性真空佈局,可支援最大1850mm基板,完美滿足中大型顯示器光罩的製程需求。

- 閉環環境控制室全程維持最佳工藝條件,確保光罩品質持續穩定,批復一批保持高度一致性。

- VPG+ 1400/1850 FPD支援全工業標準資料格式,可與您現有設計製造流程實現無縫對接。

投資顯示器應用技術的未來

VPG+ 1400 FPD與VPG+ 1850 FPD是對您顯示器生產能力的戰略性投資。通過引入這些系統,您將實現:

- 卓越光罩品質,成就無瑕顯示器應用性能

- 高效生產,滿足大規模顯示器生產需求並提升量產能力

- 極具經濟效益的設備價格,顯著降低生產成本

- 穩定可靠的設備運行與卓越性能表現

- 面向未來的技術架構,適配新一代顯示器技術的反覆運算需求

為您的顯示器製造提供高性價比的工具

立即聯繫我們,探索VPG+系統如何加速您的光罩生產進程。

突破光罩的限制、成本和延遲。VPG 300 DI 是一款高性能直寫光刻系統,助您將創新週期從數周縮短至數小時。VPG 300 DI融合傳統i-line步進式光刻機的精度優勢和無光罩工作流程的強大優勢,使研發週期能夠以無與倫比的速度和靈活性,直接在最大 300 毫米的晶片直寫,繪製高解析度微結構圖案。

步進式光刻的精度,直寫技術的自由

VPG 300 DI完美彌合研發與生產的差距。它既具備基於光罩的步進式光刻機所擁有的亞微米級解析度和嚴格套刻精度,又徹底消除了光罩採購帶來的高昂成本與交期延誤。這使它成為快速原型、工藝開發和需要頻繁設計反覆運算需求的理想解決方案。

從 CAD 設計到曝光只需幾分鐘,而不是幾周

VPG 300 DI讓您實現設計構思的即時轉化,將傳統數周週期壓縮至分鐘級別。先進光學引擎支援每日測試新設計,徹底改變加快開發進度。

-

高速曝光:

定制的空間光調製器 (SLM) 和優化的資料路徑,使您只需 9 分鐘即可寫入 100×100 mm²的區域。 -

無縫大面積加工:

支持無尺寸限制的大面積器件製備,徹底規避步進式光刻固有的拼接誤差。 -

即時更改設計:

CAD 檔修改立即開始曝光。無需經歷新光罩訂購、等待、檢查和存儲。

實現卓越的特徵保真度

您的研究需要極致精度。VPG 300 DI基於成熟的VPG+平台打造,配備高穩定性Zerodur®載台,即使是要求最嚴苛的微結構也能提供出色品質。

-

高解析度:

穩定製備500納米以下的精細結構。 -

卓越的邊緣品質:

邊緣粗糙度< 40 nm (3σ)。 -

出色的CD均勻性:

嚴格的工藝控制,CD 均勻度< 50 nm (3σ)。

智慧工具賦能複雜器件製造

從多層MEMS到先進封裝工藝,VPG 300 DI配備精密的系統解決方案,確保整個基板範圍內的完美對準和聚焦。

-

自動多層對準:

實現正面對準精度達 100 nm。該系統還支援埋入結構優化設計,支援可見光(VIS)與紅外(IR)雙模式背面對準。 -

動態自動對焦:

可選擇光學或氣動自動對焦模式,動態補償晶圓翹曲或形貌變化> 160 µm,確保全域對焦清晰。 -

綜合計量:

即時測量位置、關鍵尺寸(CD)及邊緣粗糙度,提供即時的工藝回饋。 -

環境穩定性:

帶有軟體補償功能的集成流場控制箱和環境感測器,可確保長期穩定的寫入結果。

準備好突破光罩工藝瓶頸了嗎?

VPG 300 DI將如何革新您的製造流程?請聯繫我們的技術專家,瞭解直寫光刻技術如何加速您的研發突破。

PRODUCT HIGHLIGHTS

Maximum substrate size: 8” (VPG+ 200) and 16” (VPG+ 400) respectively Minimum feature size: Down to 0.75 μm Address grid: Down to 12.5 nm Maximum write speed (at structure size 4 um): 13500 mm²/min Exchangeable write modes Real-time autofocus system High power DPSS laser with 355 nm wavelength Camera system for metrology and alignment Closed-loop climate chamber Automatic substrate loading system Stage map correction Edge detector system Multiple data input formats (DXF, CIF, GDSII and Gerber)

Maximum substrate size: 800 x 800 mm² / 1100 x 1100 mm² / 1400 x 1400 mm² Minimum feature size: Down to 0.75 μm Maximum write speed (at 4 μm feature size): 16500 mm² / min Real-time autofocus system High power DPSS laser with 355 nm Camera system for metrology and alignment Closed-loop environmental chamber Automatic substrate loading system Stage map correction Mura correction Edge detector system Multiple data input formats (DXF, CIF, GDSII and Gerber files)

曝光速度

100×100 mm²區域寫入僅需9分鐘

曝光品質

邊緣粗糙度<40nm,CD 均勻度<50 nm,解析度< 500 nm

對準精度

第二層正面對準精度達 100 nm,背面 VIS / IR ±1 µm

智慧對準系統

全域/局部自動對準及畸變校正;VIS 背面對準;紅外(IR)對準適用於埋入結構

自動對焦

可選光學/氣動對焦模式,動態補償能力> 160 µm

集成計量功能

即時監測位置、CD及邊緣粗糙度

寫入的穩定性

集成環境計量、流場控制箱和軟體修正功能,以補償環境變化

AVAILABLE MODULES

Micro-optics MEMS Display Micro sensor

Micro-optics MEMS Display Micro sensor

Automatic handling options

Open frame handling with SEMI standard carriers and prealigning available for 100 to 200 mm or 200 / 300 mm standard wafers (others on request)

Two write modes to choose from

High NA for highest resolution or lower NA optimized for throughput or DOF critical applications

Alignment options

VIS and IR backside alignment

Service Contracts

Worldwide service level agreements for faster on-site support and access to spare parts

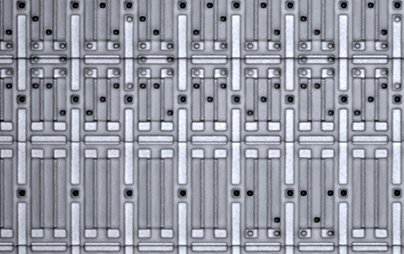

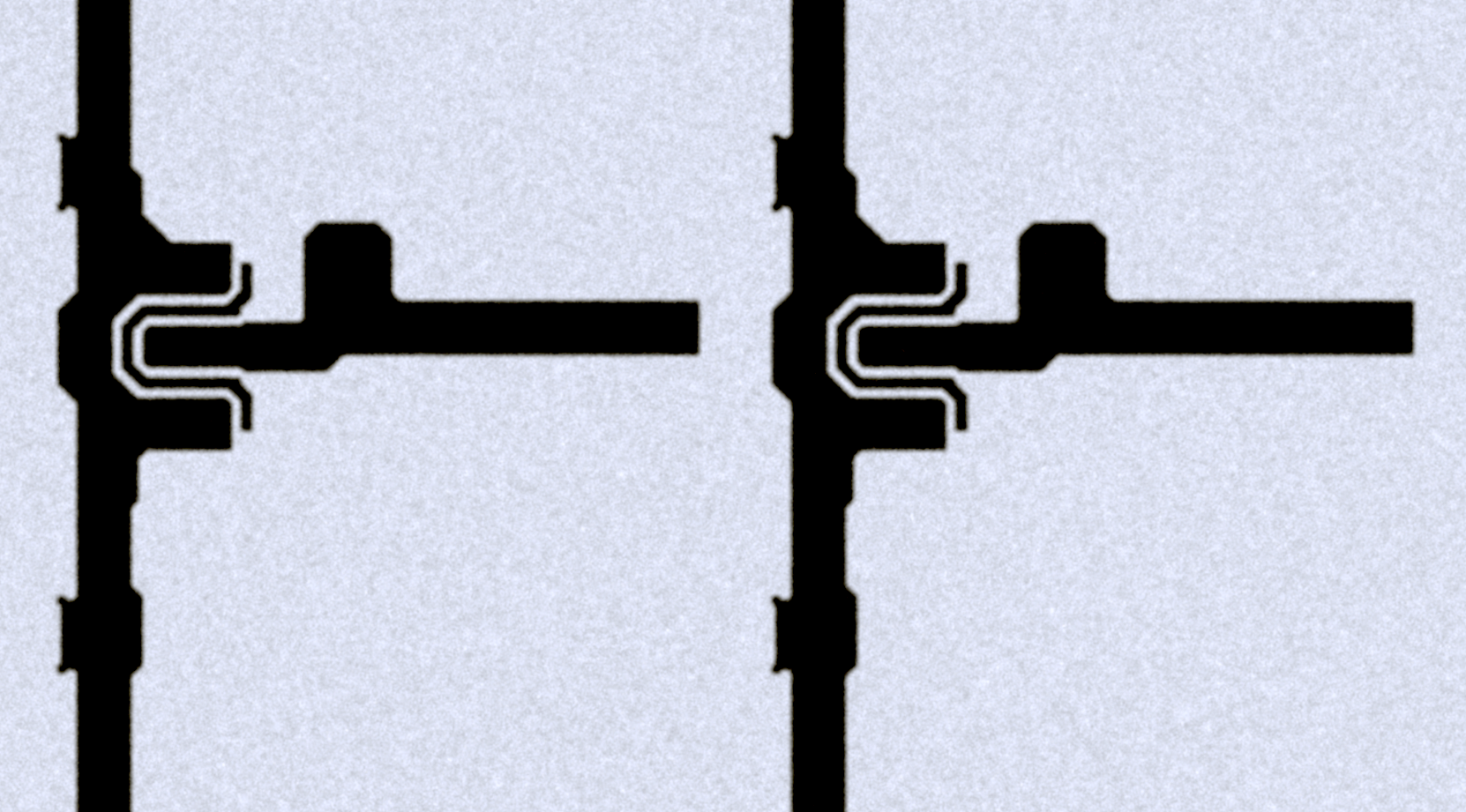

The IMS Gate Forest® technology is a “sea-of-gates” mixed-signal gate array integrating analog and digital functionality on a single chip. The microelectronic elements on the master can be individually configured by adding the respective contacts.In a Mix & Match-approach, stepper lithography patterned the CMOS masters, and personalized contacts and metallization layers were added using VPG+ 400 laser lithography.

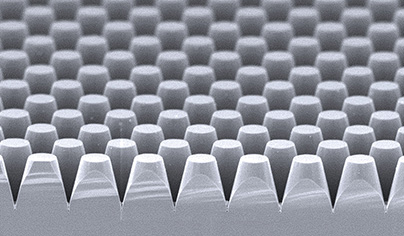

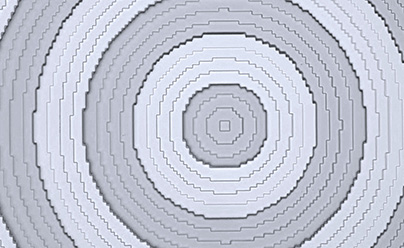

A full 150-mm-wafer filled with a hexagonal pillar array. In such 2D replication master, no visible stitching errors are allowed. The resulting circular structures have a diameter of around 1.7 μm at the top and around 3 μm at the pitch.(Courtesy of IMS Chips)

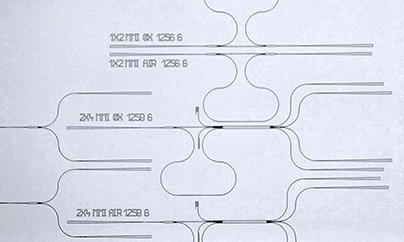

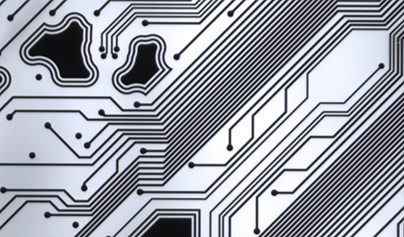

Waveguides for Photonics applications created using Mix-and-Match-approach with both e-beam and laser lithography.(Courtesy of IMS Chips)

The VPG+ series can be used for all display-related applications. In this field, the quality requirements on photomasks are exceptional. One key specification is the so-called Mura condition, describing 'unevenness' as a result of any disturbance in a regular periodic pattern. If the Mura condition fails to meet the requirements, the final display might have dark spots or patches. The V series of Maskless Lithography Systems offers a special Mura optimization function for good Mura condition, excellent CD uniformity, and resolution.

The VPG+ 200 and VPG+ 400 present the solution to fabricate high-quality photomasks required for advanced packaging applications. For some applications, e.g., Through-Silicon Via (TSV) for 3D-integrated circuits, direct write lithography is currently the only available advanced packaging solution. The VPG+ 200 and the VPG+ 400 maskless lithography systems offer high speed, automatic distortion compensation and excellent resolution in order to master these applications.

8-level quartz Diffractive Optical Element (DOE) exposed using VPG+ system. The pixels are about 2 μm in size, the array of devices covers an area of about 20 mm.(Courtesy of IMS Chips)

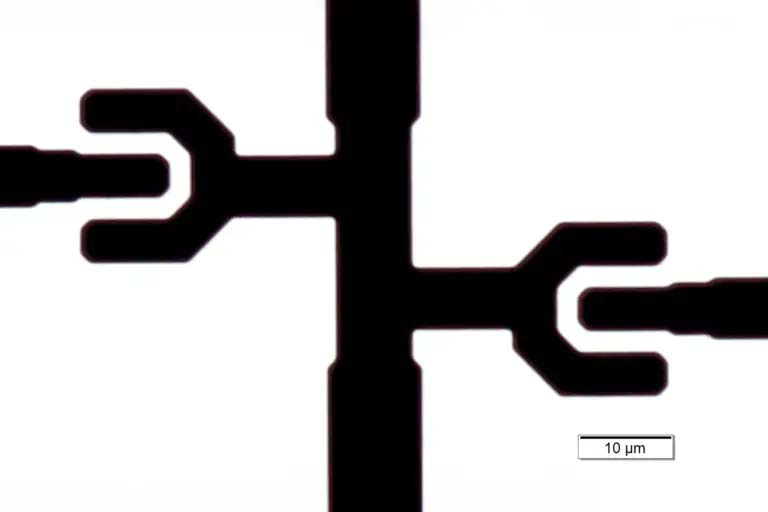

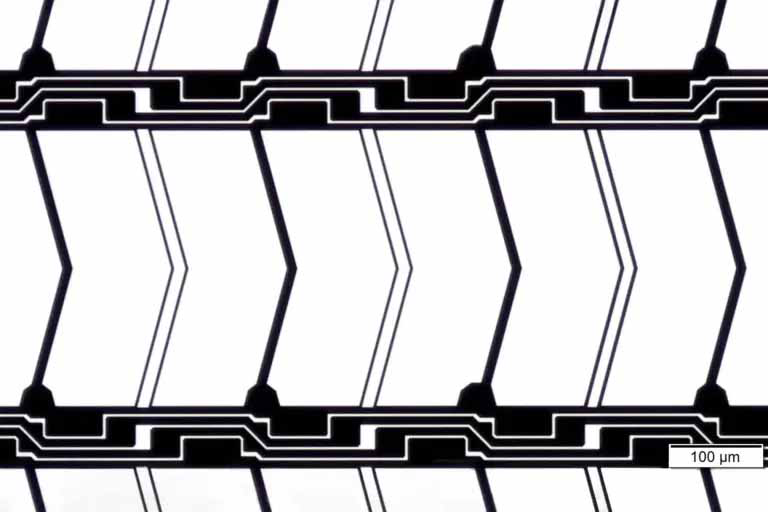

Display application pattern on chrome mask after etching and resist stripping.

Display application pattern on chrome mask after etching and resist stripping.

Reach Us

想要知道更多資訊嗎? 沒問題,快與我們聯繫!

© Stella Technology Co., Ltd.